Our Services

Process Improvement

"Combine Six Sigma, Lean, Quality Management, Facility Planning, and Economic Analysis tools to increase business value and reduce waste"

What is Process Improvement?

“Process improvement” means making things better, not just fighting fires or managing crises. It means setting aside the customary practice of blaming people for problems or failures. It is a way of looking at how we can do our work better.

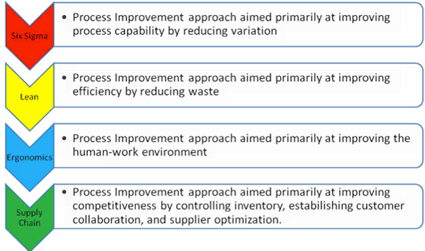

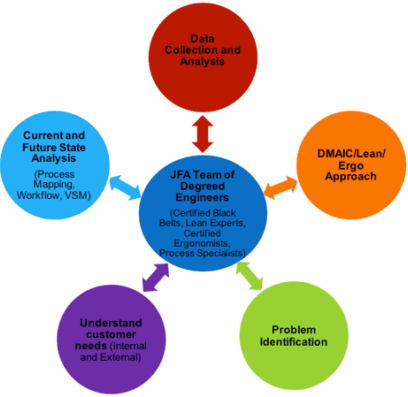

Holistic Process Improvement Approach: Holism is the idea that all the properties of a given system (physical, biological, chemical, social, economic, mental, linguistic, etc.) cannot be determined or explained by its component parts alone. Instead, the system as a whole determines in an important way how the parts behave. Synonymously, Process Improvement can be successfully achieved only by considering Six Sigma, Lean, Ergonomics, and Supply chain and their interaction with one another.

Holistic Process Improvement Approach

SIX Sigma

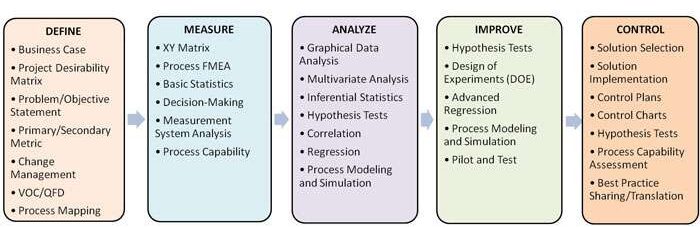

DMAIC Process in Six-Sigma

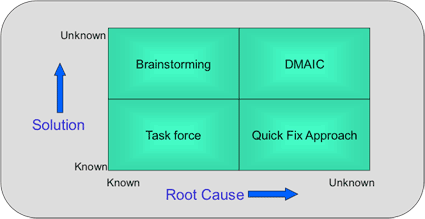

Selection the correct approach for the type of problem

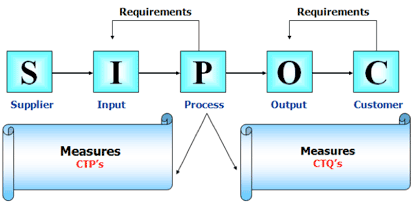

High-Level Process Mapping

The SIPOC tool is particularly useful when it is not clear:

- Who supplies inputs to the process?

- What specifications are placed on the inputs?

- Who are the true customers of the process?

- What are the requirements of the customers?

Lean

Ergonomics

- Six Sigma

- Lean

- Quality Management

- Facility Planning

- Economic Analysis

Six Sigma

Six Sigma is an improvement approach aimed primarily at improving process capability by reducing/eliminating variation.

Six Sigma Process

Lean

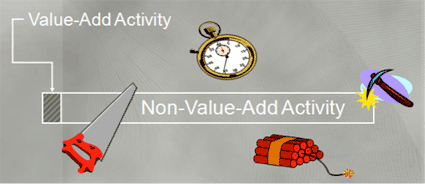

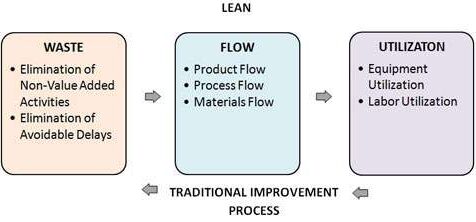

Lean is an improvement approach aimed primarily at improving efficiency by removing wastes.

Lean vs. Traditional Improvement Process

Quality Management

Quality Management aims in achieving long-term success through customer satisfaction. The basis of the approach is to:

- Reduce the errors produced during the manufacturing or service process

- Increase customer satisfaction

- Streamline supply chain management

- Aim for modernization of equipment

- Ensure workers have the highest level of training

Quality management looks to answer the following:

- How do you satisfy the customer?

- Why should you satisfy the supplier?

- What is continuous improvement?

Facility Planning

The purpose of facility planning is to determine the optimal locations of machines, processes, and workers to help reduce waste, optimize efficiency, and improve flow. This process can include the use of various tools such as network diagrams, weighted path analysis, determination of work-in-process, etc.

The experts at JFA are trained Industrial Engineers and can provide the following services:

- Facilities Design and Layout

- Work and Material flow analysis

- Material Handling systems and equipment selection

- Overall Supply Chain efficiency

- Warehouse Operations

Economic Analysis

Economic analysis is a systematic approach to determining the optimum use of scarce resources, involving comparison of two or more alternatives in achieving a specific objective under the given assumptions and constraints

Economic analysis takes into account the opportunity costs of resources employed and attempts to measure in monetary terms the private and social costs and benefits of a project to the community or economy.

The experts at JFA can provide the following economic analysis services:

- Benefit-Cost Analysis

- Break-Even Analysis

- Economic Impact Analysis

- Budget Reviews and cost estimations